It is a long established fact that a reader will be distracted by the readable content of a page when looking at its layout. The point of using Lorem Ipsum is that it has a more-or-less normal distribution of letters, as opposed to using 'Content here, content here', making it look like readable English. Many desktop publishing packages and web page editors now use Lorem Ipsum as their default model text, and a search for 'lorem ipsum' will uncover many web sites still in their infancy. Various versions have evolved over the years, sometimes by accident, sometimes on purpose (injected humour and the like).

“Give me ONE second!”

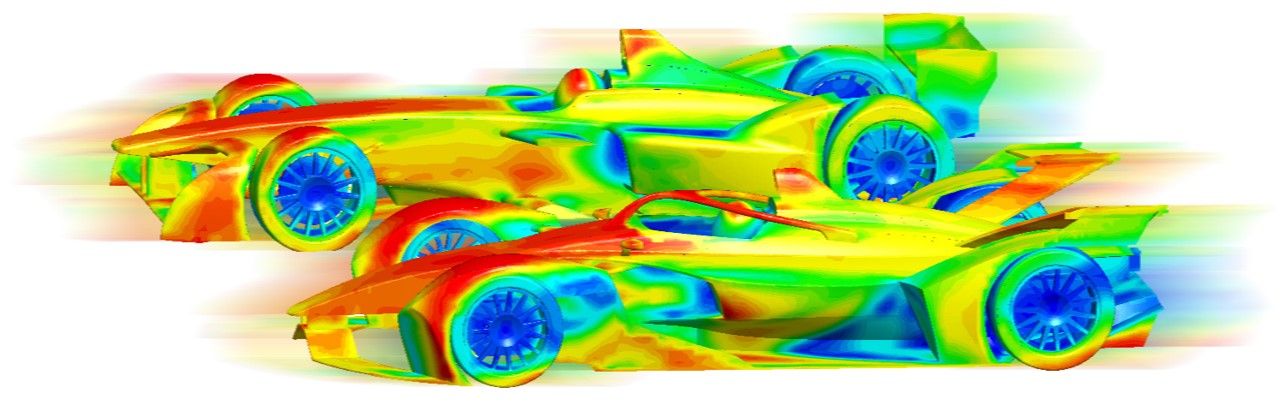

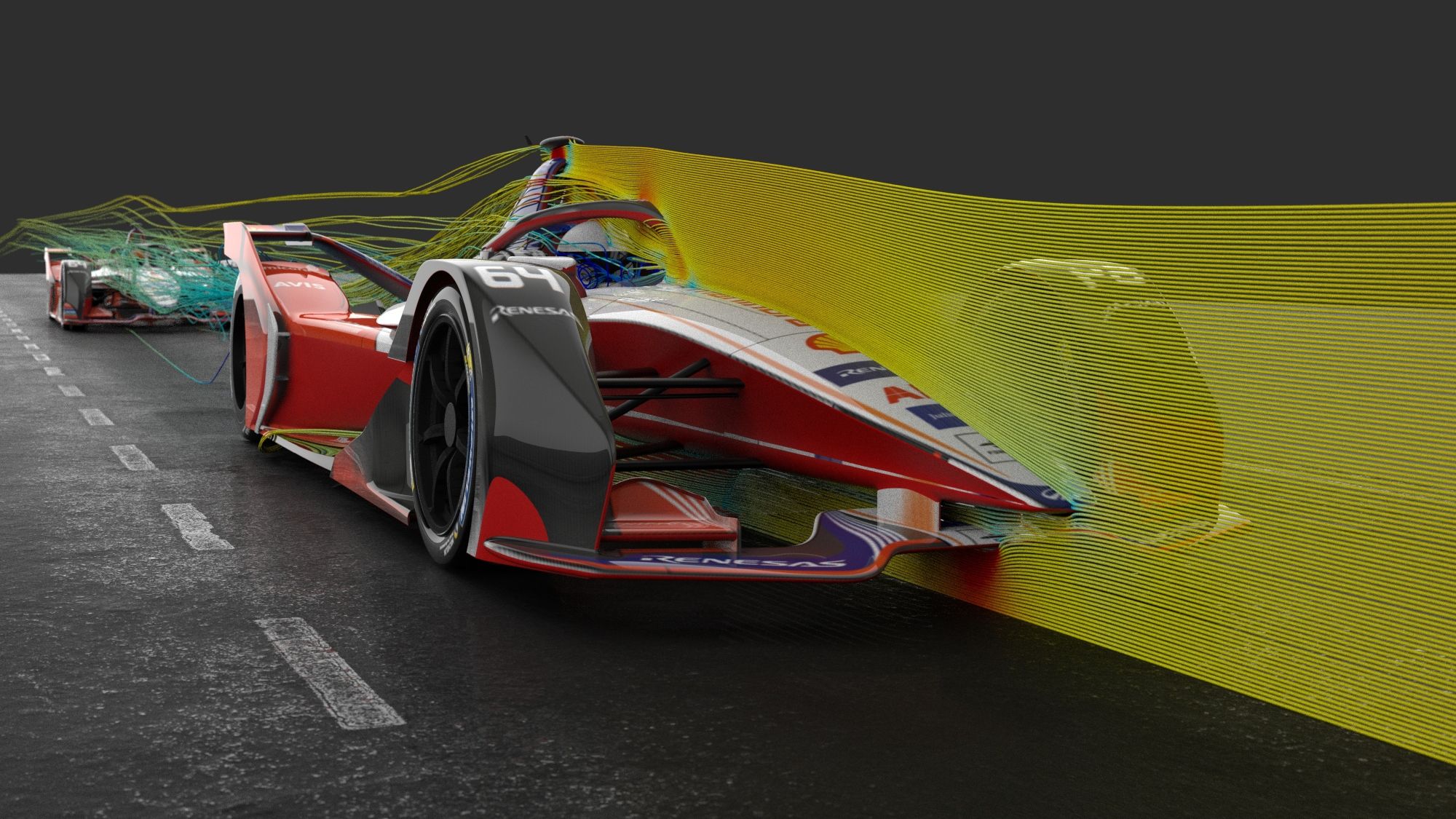

Voxdale has designed and developed the 12V auxiliary battery which enables all of the mission critical systems to be run on the Formula E cars. Besides extensive aerodynamic efficiency simulation and other testing techniques, other work for Mahindra Racing includes the optimisation and design of the gearbox casing and the building of the body for the simulator.

Dilbagh Gill, CEO & Team Principal, Mahindra Racing

Formula E is a full electric single seater racing series and was established in 2011. Mahindra Racing was one of the first seven teams driving in this world championship with races in 5 continents. Today, all major constructors and car manufacturers have entered the championship. Driven by the clear and clean sustainability message, all of them are displaying the newest technologies in electric driving. The rule book and regulations of this racing series are well defined and very different than F1.

As a team you’re not allowed to further develop the chassis. The main battery is the same for all competitors and also brakes, tires, and suspension are standard parts. Constructor can however design and build their own powertrain, work on their setups and setting and design and construct the 12V auxiliary secondary battery that powers the electronic systems for all the mission critical systems in the car.

Typically, Formula E teams employ 40 to 60 people, and spending costs are not more than 10% of that of an F1 team. Keeping cost reduction scenario’s in F1 in mind, this is a great position to be in as a manufacturer.

The challenge of designing and engineering powertrain concepts, is the technological challenge that excites and differentiates the constructors. Very importantly and linked to that is a homologation freeze every year, making ‘time’ a trigger for fast development.

One second is all it takes!

Approach

In November 2017, Voxdale, Umicore and racing driver Sam Dejonghe announced their partnership with Mahindra Racing in the Formula E Championship. Since then, Voxdale and Mahindra Racing engineers have been working together to apply Voxdale’s areas of expertise such as Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD) and simulation techniques to further tune the performance of the electric race cars.

Result

Voxdale has designed and developed the 12V auxiliary battery which enables all of the mission critical systems to be run on the Formula E cars. Besides extensive aerodynamic efficiency simulation and other testing techniques, other work for Mahindra Racing includes the optimisation and design of the gearbox casing and the building of the body for the simulator.